Little Lift

We were prompted to design a mass-efficient machine that drops a heavy weight 0.1m to lift a 1kg weight up one meter. We designed a 3D printed housing, incorporating purchased components, with an input of 30lb/13.6kg.

My team was awarded the most mass-efficient design!

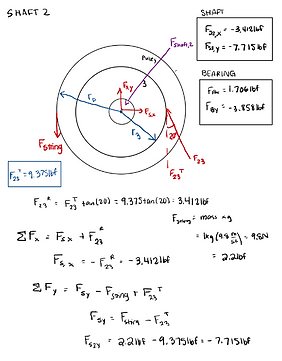

Gear Ratio

To create the desired motion, our group pursued a 3 gear train with a rack actuator. Based on available components for purchase and desired output we calculated the gear ratios and force input needed.

Designing Housing

We then brainstormed various housings for the purchased components but ran into a force imbalance which would result in tipping, but this was addressed with a triangular kickout. For the location of weight input, we designed a rod with with a small plate that would guide the weight to stay centrally loaded.

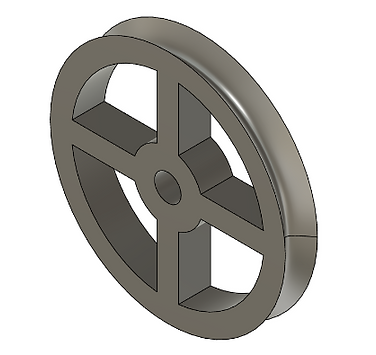

Finalized CAD

FEA Analysis

Before 3D printing the components, we ran FEA analysis on the body, rack attachment, and pulley. Based on these, we moved forward with our design as it would not experience concerning amounts of stress or displacement.

Materials Management

An important part of this project was component selection and purchasing. I took the lead on this and learned about material attributes, staying organized, and communicating with outside purchasers.

Finalized Design + Testing

Acknowledgments

-

My Team Members, Janelle Baker, Eric Jones, Zak Werdeger

-

Stanford University, Steve Collins