Double Buckle

A swappable belt buckle manufactured on CNC using brass and aluminum. The buckle designs attached to the connector using a threading mechanism. The brass buckle design is inspired by my ethnic background and the Sierra Leonean emblem of the Coat of Arms. The Aluminum design is inspired by Paul Frank, a childhood icon in the likes of Hello Kitty and Domo.

How it Works

Initial Ideation

Jewelry Box

Stackable Glasses Display

Interchangeable Belt Buckle

For the project, we were given no prompt and only the requirement to make a product with a mechanical connection or interface. I was inspired by a range of ideas, but decided to expand on the idea of an interchangeable belt buckle I had worked on in the past.

CAD and Prototyping

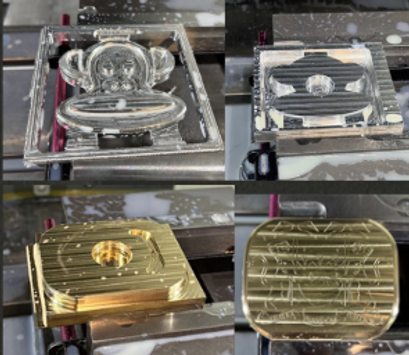

First I prototyped the key connections: between the face and between the purchased component. It took a while to tune the threads on the 3D printer, but these ended up working well which didn't necessarily translate into my final design. Then, I added heat set inserts to my PLA component to test the spacing of the threaded holes I would need because the purchased component did not come with these dimensions.

Then, I did an aesthetic prototype to see what my designs would actually end up looking like, which I loved. However, to reduce machining time I had to make the coat of arms design 2D.

Manufacturing

I had to manufacture 3 pieces on the CNC, each with one part flip, which luckily reduced the chance for offsets. Two were made of aluminum and one of brass. The total time spent machining was around 12 hours. Manufacturing these on the CNC was a tough process, especially figuring out workholding and having to add tabs to all of my designs.

Post Processing + Finishing

Because of errors in my operation, the finish on the Paul Frank Buckle was not what I expected. To get the aesthetics I wanted, I sanded, polished, and sandblasted various parts of the design.

The drill bit used in one of my operations ended up being misplaced in the drawer and resulted in a hole that the CNC could not thread. As a result, I had to helicoil two of the holes in order to secure my purchased component that actually allowed my product to function as a belt buckle.

Final Product

Takeaways

-

Prototype threads and connections on the CNC, if you can! Prototypes of a different manufacturing process don't always teach you what you need to know.

-

When finishing a piece, it's important to think about the order of operations! Finish polishing before sandblasting other parts.

-

Think through the order of CNC operations, especially in finishing operations.