Glass Crusher

A half-year long group project under the organization Engineers for a Sustainable World. Contracted by The Maa Trust in Masaai Mara, Kenya to design a more efficient device to crush glass into fine sand particles than the crusher previously used in the area.

Background

Glass Bottles

(wine, beer, etc.)

Sand

Bricks

Houses

The Maa Trust in Maasai Mara, Kenya is a nonprofit organization focused on wildlife conservation and collaborating with the local community. Their need for a glass crusher arose due to an abundance of glass that needed to be safely disposed of. Crushing them into sand made the bottles useful and contributed to the creation of Maa Bricks program. The sand would be used to make bricks which could then make houses providing multiple business opportunities that can lead to economic empowerment for the women and young adults who would be a part of the process.

Initial Brainstorm, Sketches, and Prototypes

When thinking about the type of mechanisms that we could use for crushing we realized that having a initial process to break the bottle into fragments would be important and also the most feasible.

For this initial breaking mechanism, we considered a Jaw Crusher, Pulverizer, and Crank Shaft motion. However, we settled on the crank shaft in the end.

For the fine crushing that would take these glass shards to sand, we quickly decided on the impact mill.

Pulverizer

The pulverizer was the first primary crushing mechanism that we looked at, but we quickly diverted after considering weight of the device, the labor needed, and the effectiveness.

Crank Shaft

The crank shaft mechanism went through many adaptations.

The sketch on the top left was during our first phase where we looked at angling the base so that the crushed pieces could slide into the finer crushing process.

The sketches on the right were after a major turning point as we talked to a Kenyan Engineer, Kirumba Muita, who thought that powering the crank shaft through cycling could help address the problem of unreliable electicity.

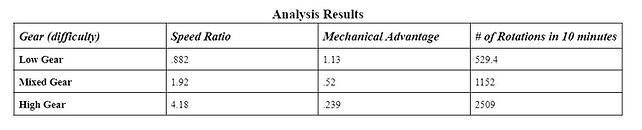

After considering a bike powered mechanism, we did an analysis on different bike gear settings and its plausibility due to our concerns of physical intensity.

We found that a mixed gear setting would be best as it still fostered a large amount of force, but balanced it with the frequent contact with the bottle.

Jaw Crusher

The jaw crusher mechanism was a strong contender for the primary crushing mechanism. However, concerns with powering the mechanism and also its construction ruled it out.

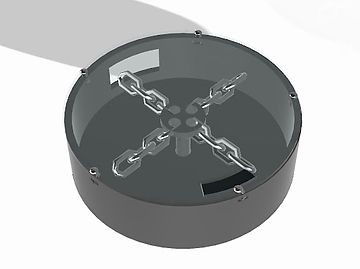

Impact Mill

These videos show an evolution of the Impact mill from our foamcore model to the final model with metal chains and a 3D printed body that is crushing chips. This device became a big part of our project after the same meeting with the engineer Kirumba Muita who said that in his practice he uses something similar. The only future concern is that the device requires electricity for it to reach a fast enough rpm, which means that it is not accessible at all times.

Reflections

-

I learned the importance of consulting professionals and experts in a field, especially in the location that you are working in.

-

I learned about working with an outside, international, organization and the importance of consistent communication.

-

I improved on my presentation skills and applied my skills learned in class to a real project.

Acknowledgements

-

My Team Members, Caitin Ramos, Katelyn Chen, Calvin Zau

-

Maa Trust, Dr. Crystal Mogensen, Isen Kipetu, Delphin Mukira

-

Stanford University, Shoshanah Cohen, D’Arcy Seamon, Teja Tripuraneni, Ananya Sridhar

-

Constructive Plastics LTD, Kirumba Muita